There are several components common to most types of reactors:

Fuel. Uranium is the basic fuel. Usually pellets of uranium oxide (UO2) are arranged in tubes to form fuel rods. The rods are arranged into fuel assemblies in the reactor core.

* In a new reactor with new fuel a neutron source is needed to get the reaction going. Usually this is beryllium mixed with polonium, radium or other alpha-emitter. Alpha particles from the decay cause a release of neutrons from the beryllium as it turns to carbon-12. Restarting a reactor with some used fuel may not require this, as there may be enough neutrons to achieve criticality when control rods are removed.

Moderator. This is material in the core which slows down the neutrons released from fission so that they cause more fission. It is usually water, but may be heavy water or graphite.

Control rods. These are made with neutron-absorbing material such as cadmium, hafnium or boron, and are inserted or withdrawn from the core to control the rate of reaction, or to halt it.* In some PWR reactors, special control rods are used to enable the core to sustain a low level of power efficiently. (Secondary shutdown systems involve adding other neutron absorbers, usually as a fluid, to the system.)

* In fission, most of the neutrons are released promptly, but some are delayed. These are crucial in enabling a chain reacting system (or reactor) to be controllable and to be able to be held precisely critical.

Coolant. A liquid or gas circulating through the core so as to transfer the heat from it. . In light water reactors the water moderator functions also as primary coolant. Except in BWRs, there is secondary coolant circuit where the steam is made. (see also later section on primary coolant characteristics)

Pressure vessel or pressure tubes. Usually a robust steel vessel containing the reactor core and moderator/coolant, but it may be a series of tubes holding the fuel and conveying the coolant through the moderator.

Steam generator. (not in BWR) Part of the cooling system where the primary coolant bringing heat from the reactor is used to make steam for the turbine. Reactors may have up to four "loops", each with a steam generator.

Containment. The structure around the reactor core which is designed to protect it from outside intrusion and to protect those outside from the effects of radiation in case of any malfunction inside. It is typically a metre-thick concrete and steel structure.

There are several different types of reactors as indicated in the following Table.

Nuclear power plants in commercial operation

| Reactor type | Main Countries | Number | GWe | Fuel | Coolant | Moderator |

| Pressurised Water Reactor (PWR) | US, France, Japan, Russia, China | 265 | 251.6 | enriched UO2 | water | water |

|---|---|---|---|---|---|---|

| Boiling Water Reactor (BWR) | US, Japan, Sweden | 94 | 86.4 | enriched UO2 | water | water |

| Pressurised Heavy Water Reactor 'CANDU' (PHWR) | Canada | 44 | 24.3 | natural UO2 | heavy water | heavy water |

| Gas-cooled Reactor (AGR & Magnox) | UK | 18 | 10.8 | natural U (metal), enriched UO2 | CO2 | graphite |

| Light Water Graphite Reactor (RBMK) | Russia | 12 | 12.3 | enriched UO2 | water | graphite |

| Fast Neutron Reactor (FBR) | Japan, Russia | 2 | 1.0 | PuO2 and UO2 | liquid sodium | none |

| Other | Russia | 4 | 0.05 | enriched UO2 | water | graphite |

| TOTAL | 439 | 386.5 |

ADVANCED REACTOR

Several generations of reactors are commonly distinguished. Generation I reactors were developed in 1950-60s and very few are still running today. They mostly used natural uranium fuel and used graphite as moderator. Generation II reactors are typified by the present US fleet and most in operation elsewhere. They typically use enriched uranium fuel and are mostly cooled and moderated by water. Generation III are the Advanced Reactors, the first few of which are in operation in Japan and others are under construction and ready to be ordered. They are developments of the second generation with enhanced safety.

Generation IV designs are still on the drawing board and will not be operational before 2020 at the earliest, probably later. They will tend to have closed fuel cycles and burn the long-lived actinides now forming part of spent fuel, so that fission products are the only high-level waste. Many will be fast neutron reactors.

More than a dozen (Generation III) advanced reactor designs are in various stages of development. Some are evolutionary from the PWR, BWR and CANDU designs above, some are more radical departures. The former include the Advanced Boiling Water Reactor, a few of which are now operating with others under construction. The best-known radical new design is the Pebble Bed Modular Reactor, using helium as coolant, at very high temperature, to drive a turbine directly.

Considering the closed fuel cycle, Generation 1-3 reactors recycle plutonium (and possibly uranium), while Generation IV are expected to have full actinide recycle.

NUCLEAR REACTORS FOR PROCESS HEAT :

Producing steam to drive a turbine and generator is relatively easy, and a light water reactor running at 350°C does this readily. As the above section and Figure show, other types of reactor are required for higher temperatures. A 2010 US Department of Energy document quotes 500°C for a liquid metal cooled reactor (FNR), 860°C for a molten salt reactor (MSR), and 950°C for a high temperature gas-cooled reactor (HTR). Lower-temperature reactors can be used with supplemental gas heating to reach higher temperatures, though employing an LWR would not be practical or economic. The DOE said that high reactor outlet temperatures in the range 750 to 950°C were required to satisfy all end user requirements evaluated to date for the Next Generation Nuclear Plant.

APLICATIONS : While PBMR's research and development efforts were initially focused mainly on electricity generation, it has become increasingly apparent that the high-temperature, gas-cooled reactor technology will also enable access to markets that call for process heat applications. Next-generation high-temperature reactors such as the PBMR can produce hydrogen for transportation or for upgrading coal and heavy crude oils into usable products, thereby relieving pressure on natural gas supply (the source of most hydrogen produced today). They can also generate process heat for desalination, to extract oil from tar sands, and for many other industrial applications.

PRIMITIVE REACTORS:

The world's oldest known nuclear reactors operated at what is now Oklo in Gabon, West Africa. About 2 billion years ago, at least 17 natural nuclear reactors achieved criticality in a rich deposit of uranium ore. Each operated at about 20 kW thermal. At that time the concentration of U-235 in all natural uranium was 3.7 percent instead of 0.7 percent as at present. (U-235 decays much faster than U-238, whose half-life is about the same as the age of the Earth.) These natural chain reactions, started spontaneously by the presence of water acting as a moderator, continued for about 2 million years before finally dying away.

During this long reaction period about 5.4 tonnes of fission products as well as 1.5 tonnes of plutonium together with other transuranic elements were generated in the orebody. The initial radioactive products have long since decayed into stable elements but close study of the amount and location of these has shown that there was little movement of radioactive wastes during and after the nuclear reactions. Plutonium and the other transuranics remained immobile.

The power rating of a nuclear power reactor

Nuclear power plant reactor power outputs are quoted in three ways:

Thermal MWt, which depends on the design of the actual nuclear reactor itself, and relates to the quantity and quality of the steam it produces.

Gross electrical MWe indicates the power produced by the attached steam turbine and generator, and also takes into account the ambient temperature for the condenser circuit (cooler means more electric power, warmer means less). Rated gross power assumes certain conditions with both.

Net electrical MWe, which is the power available to be sent out from the plant to the grid, after deducting the electrical power needed to run the reactor (cooling and feed-water pumps, etc.) and the rest of the plant.*

* footnote: This (as also actual gross MWe) varies slightly from summer to winter, so normally the lower summer figure, or an average figure, is used. If the summer figure is quoted plants may show a capacity factor greater than 100% in cooler times. Some design options, such as powering the main large feed-water pumps with electric motors (as in EPR) rather than steam turbines (taking steam before it gets to the main turbine-generator), explains some gross to net differences between different reactor types. The EPR has a relatively large drop from gross to net MWe for this reason.

The relationship between these is expressed in two ways:

- Thermal efficiency %, the ratio of gross MWe to thermal MW. This relates to the difference in temperature between the steam from the reactor and the cooling water. It is often 33-37%.

- Net efficiency %, the ratio of net MWe achieved to thermal MW. This is a little lower, and allows for plant usage.

In WNA papers and figures and WNN items, generally net MWe is used for operating plants, and gross MWe for those under construction or planned/proposed.

Pressurised Water Reactor (PWR)

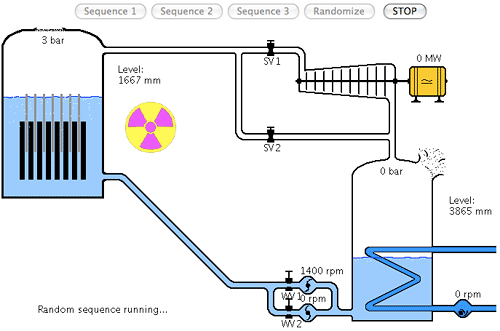

This is the most common type, with over 230 in use for power generation and several hundred more employed for naval propulsion. The design of PWRs originated as a submarine power plant. PWRs use ordinary water as both coolant and moderator. The design is distinguished by having a primary cooling circuit which flows through the core of the reactor under very high pressure, and a secondary circuit in which steam is generated to drive the turbine. In Russia these are known as VVER types - water-moderated and -cooled.

A PWR has fuel assemblies of 200-300 rods each, arranged vertically in the core, and a large reactor would have about 150-250 fuel assemblies with 80-100 tonnes of uranium.

Water in the reactor core reaches about 325°C, hence it must be kept under about 150 times atmospheric pressure to prevent it boiling. Pressure is maintained by steam in a pressuriser (see diagram). In the primary cooling circuit the water is also the moderator, and if any of it turned to steam the fission reaction would slow down. This negative feedback effect is one of the safety features of the type. The secondary shutdown system involves adding boron to the primary circuit.

The secondary circuit is under less pressure and the water here boils in the heat exchangers which are thus steam generators. The steam drives the turbine to produce electricity, and is then condensed and returned to the heat exchangers in contact with the primary circuit.

Boiling Water Reactor (BWR)

This design has many similarities to the PWR, except that there is only a single circuit in which the water is at lower pressure (about 75 times atmospheric pressure) so that it boils in the core at about 285°C. The reactor is designed to operate with 12-15% of the water in the top part of the core as steam, and hence with less moderating effect and thus efficiency there. BWR units can operate in load-following mode more readily then PWRs.

The steam passes through drier plates (steam separators) above the core and then directly to the turbines, which are thus part of the reactor circuit. Since the water around the core of a reactor is always contaminated with traces of radionuclides, it means that the turbine must be shielded and radiological protection provided during maintenance. The cost of this tends to balance the savings due to the simpler design. Most of the radioactivity in the water is very short-lived*, so the turbine hall can be entered soon after the reactor is shut down.

* mostly N-16, with a 7 second half-life

A BWR fuel assembly comprises 90-100 fuel rods, and there are up to 750 assemblies in a reactor core, holding up to 140 tonnes of uranium. The secondary control system involves restricting water flow through the core so that more steam in the top part reduces moderation.

Pressurised Heavy Water Reactor (PHWR or CANDU)

The PHWR reactor design has been developed since the 1950s in Canada as the CANDU, and more recently also in India. It uses natural uranium (0.7% U-235) oxide as fuel, hence needs a more efficient moderator, in this case heavy water (D2O).**

** with the CANDU system, the moderator is enriched (ie water) rather than the fuel, - a cost trade-off.

The moderator is in a large tank called a calandria, penetrated by several hundred horizontal pressure tubes which form channels for the fuel, cooled by a flow of heavy water under high pressure in the primary cooling circuit, reaching 290°C. As in the PWR, the primary coolant generates steam in a secondary circuit to drive the turbines. The pressure tube design means that the reactor can be refuelled progressively without shutting down, by isolating individual pressure tubes from the cooling circuit.

A CANDU fuel assembly consists of a bundle of 37 half metre long fuel rods (ceramic fuel pellets in zircaloy tubes) plus a support structure, with 12 bundles lying end to end in a fuel channel. Control rods penetrate the calandria vertically, and a secondary shutdown system involves adding gadolinium to the moderator. The heavy water moderator circulating through the body of the calandria vessel also yields some heat (though this circuit is not shown on the diagram above).

Newer PHWR designs such as the Advanced Candu Reactor (ACR) have light water cooling and slightly-enriched fuel.

CANDU reactors can readily be run on recycled uranium from reprocessing LWR used fuel, or a blend of this and depleted uranium left over from enrichment plants. About 4000 MWe of PWR can then fuel 1000 MWe of CANDU capacity, with addition of depleted uranium.

Advanced Gas-cooled Reactor (AGR)

These are the second generation of British gas-cooled reactors, using graphite moderator and carbon dioxide as coolant. The fuel is uranium oxide pellets, enriched to 2.5-3.5%, in stainless steel tubes. The carbon dioxide circulates through the core, reaching 650°C and then past steam generator tubes outside it, but still inside the concrete and steel pressure vessel. Control rods penetrate the moderator and a secondary shutdown system involves injecting nitrogen to the coolant.

The AGR was developed from the Magnox reactor, also graphite moderated and CO2 cooled, and two of these are still operating in UK. They use natural uranium fuel in metal form. Secondary coolant is water.

Light water graphite-moderated reactor (RBMK)

This is a Soviet design, developed from plutonium production reactors. It employs long (7 metre) vertical pressure tubes running through graphite moderator, and is cooled by water, which is allowed to boil in the core at 290°C, much as in a BWR. Fuel is low-enriched uranium oxide made up into fuel assemblies 3.5 metres long. With moderation largely due to the fixed graphite, excess boiling simply reduces the cooling and neutron absorbtion without inhibiting the fission reaction, and a positive feedback problem can arise, which is why they have never been built outside the Soviet Union.